Sonar systems demand precise signal conditioning, low-latency processing, and reliable performance in harsh and unpredictable environments. Traditional analog front ends rely on fixed-function circuitry. This can limit adaptability and increase design complexity. As sonar architectures evolve to include broadband sonar, adaptive filtering, and dynamic frequency modes, these limitations become more pronounced.

Field Programmable Analog Arrays (FPAAs) introduce a new level of flexibility. Similar to FPGAs in the digital domain, FPAAs allow engineers to reconfigure hardware. Unlike FPGAs, they operate directly on analog signals. This enables real-time filtering, amplification, and routing without the latency or power overhead of full digital conversion. For sonar engineers, FPAAs can reduce energy consumption, improve signal fidelity, and simplify hardware architectures. Applications range from underwater vehicles and robotics to industrial inspection and environmental monitoring.

Current Sonar Constraints and How FPAAs Help

Conventional sonar relies on tightly tuned analog stages. These include preamplifiers, filters, and impedance matching circuits. Multi-frequency or broadband sonar designs increase this complexity, often requiring independent analog chains, multiple discrete components, and careful environmental optimization. These constraints can lead to higher power consumption, larger physical footprint, and limited in-field adaptability. Such limitations challenge modern sonar applications like autonomous vehicles, environmental monitoring, and portable inspection platforms.

FPAAs offer a reconfigurable solution. They provide configurable analog blocks for amplification, filtering, routing, and integration. Engineers can adjust gain, bandwidth, and filter cutoffs in real time without hardware changes. This allows low-latency processing, simplified broadband sonar support, reduced component count, and overall power efficiency. In short, FPAAs address many of the constraints imposed by traditional analog front ends.

FPAA Workflow for Sonar Systems

FPAA development workflows resemble FPGA design but focus on analog signal chains. Engineers typically follow these stages:

- Analog path design: Select amplifiers, filters, integrators, and switches for the sonar's frequency bands.

- Parameter configuration: Set gains, filter cutoffs, and routing rules in software, enabling rapid iteration without hardware changes.

- Simulation and verification: Validate analog behavior across expected environmental conditions.

- Real-time reconfiguration: Control processors adjust the FPAA dynamically after deployment, supporting mode switching, noise compensation, or broadband sonar patterns.

This workflow enables continual refinement of sonar signal chains and adaptive control algorithms that respond to changing underwater environments.

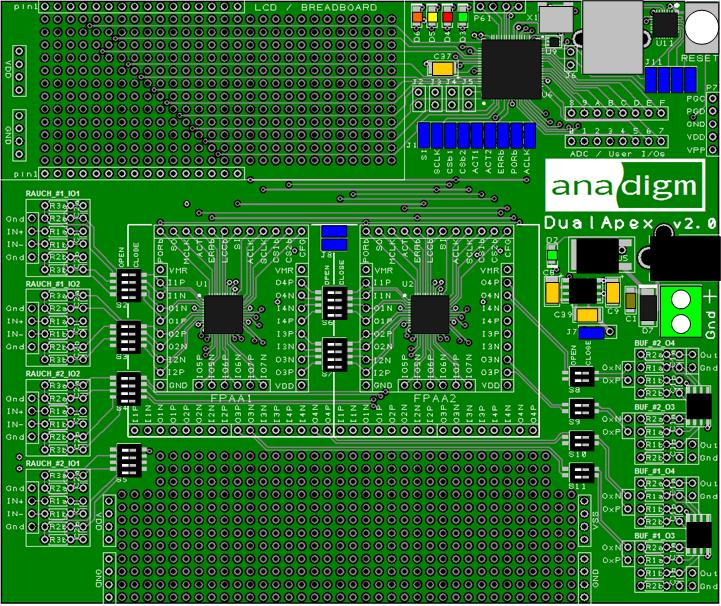

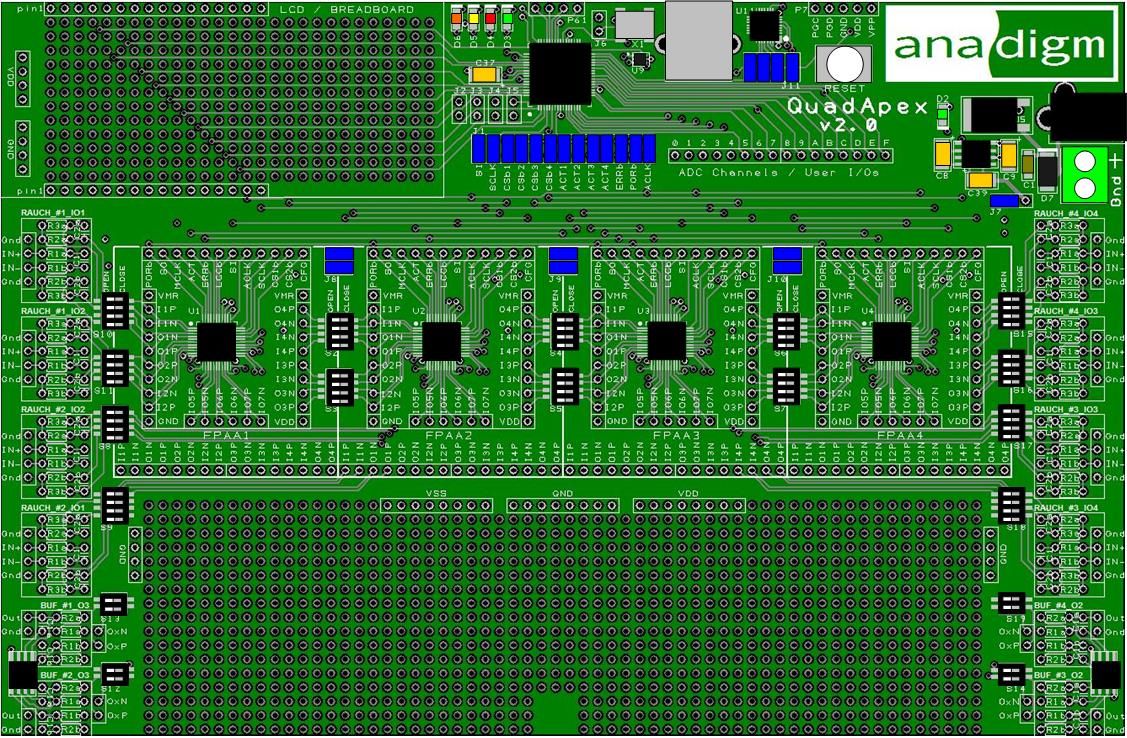

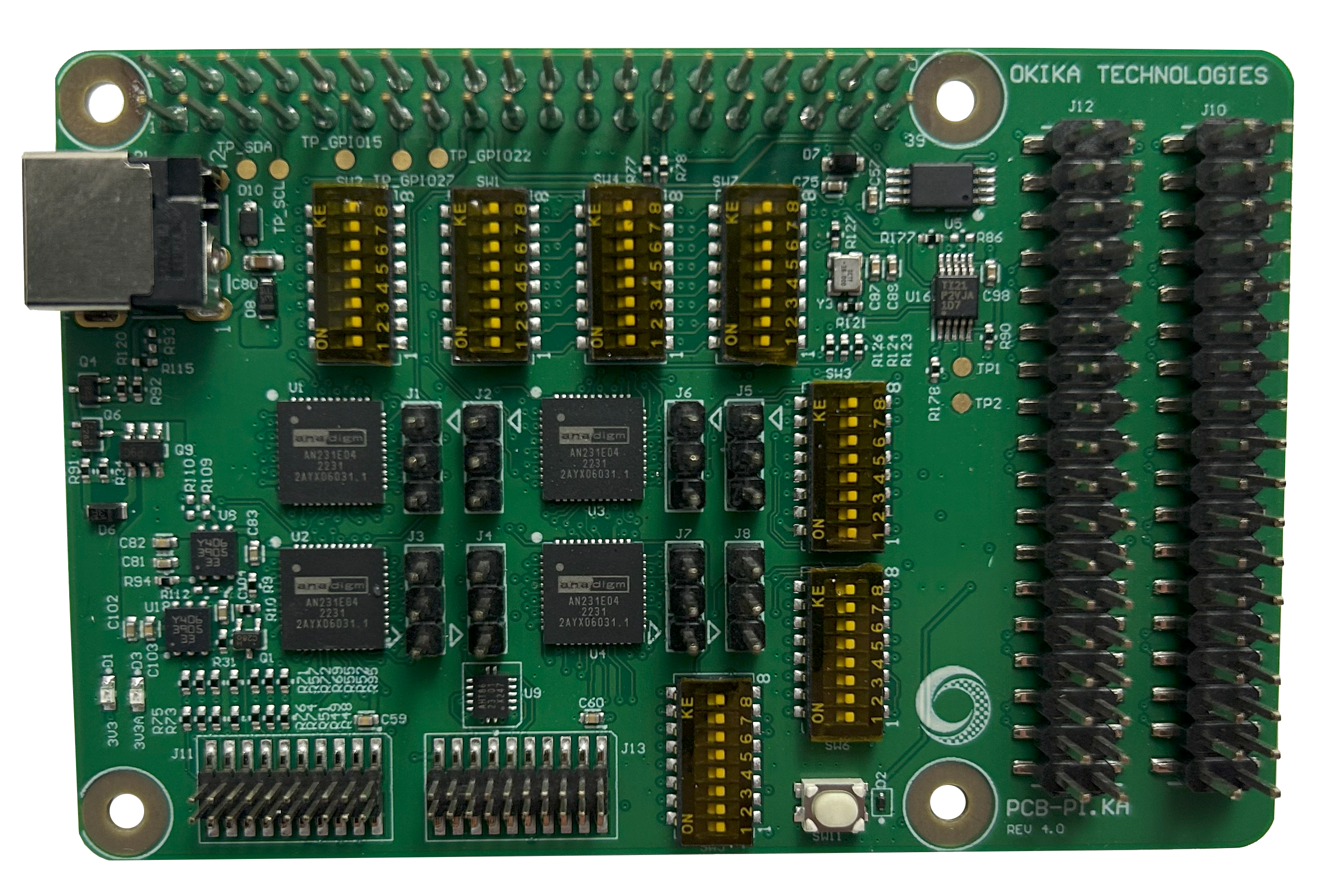

Practical FPAA Architectures in Sonar Systems

A typical sonar system pairs the FPAA as a configurable analog front end with a microcontroller or FPGA for digital post-processing. The signal path flows from the sensor through the FPAA, then to the ADC, and finally to the digital processor.

The FPAA handles real-time analog conditioning. This includes preamplification, filtering, impedance matching, and dynamic mode switching. By consolidating several analog circuits into one device, it reduces PCB area, lowers power consumption, and creates a compact, efficient design for space-constrained platforms.

FPAA programmability also allows engineers to adjust pulse frequency, bandwidth, and gain profiles entirely through software. This enables dynamic beam shaping, adaptive noise suppression, environmental compensation, and flexible multi-sensor arrays without hardware redesign.

Enabling Broadband and Adaptive Sonar

Modern sonar increasingly relies on multiple frequency bands to improve resolution, classification accuracy, and detection range. FPAAs support these capabilities in several ways.

They provide programmable filter banks that allow dynamic creation of analog paths for different frequencies. They also enable real-time mode switching for high-resolution scanning, long-range detection, or hybrid operational modes.

Adaptive noise filtering improves the signal-to-noise ratio before digitization. Per-channel conditioning supports phased arrays and beamforming systems while reducing the need for discrete components.

Modern FPAA Capabilities for Sonar

Recent FPAA designs have introduced improvements that make them ideal for advanced sonar applications. Higher bandwidth allows engineers to handle multiple frequency bands more easily. Improved linearity and dynamic range maintain signal fidelity even in high-noise conditions.

Lower power consumption makes FPAAs well suited for battery-powered underwater systems. Seamless integration with microcontrollers and FPGAs simplifies mixed-signal development.

These advancements give FPAAs the flexibility and performance needed to support mission-critical sonar systems. They deliver both analog agility and high-fidelity signal processing in a compact, efficient package.

Conclusion

Sonar systems rely on precise, adaptive analog processing. Traditional fixed-function front ends often limit flexibility, increase power usage, and complicate broadband sonar designs.

Field Programmable Analog Arrays provide a compelling alternative. By enabling programmable analog filtering, amplification, and routing, FPAAs allow sonar engineers to build compact, low-power, high-fidelity front ends that adapt in real time.

When combined with digital processors in hybrid architectures, FPAAs enable scalable, field-updatable sonar systems capable of supporting evolving operational requirements. For underwater robotics, industrial inspection, environmental monitoring, and advanced broadband sonar arrays, FPAAs offer a practical path to resilient, efficient, and future-proof designs.