Power efficiency is a critical consideration in modern electronics, particularly in sectors such as aerospace, robotics, medical devices, and industrial IoT. Analog signal processing often consumes significant energy due to multiple discrete components performing amplification, filtering, and routing. Traditional analog designs can require numerous integrated circuits, each drawing its own supply current.

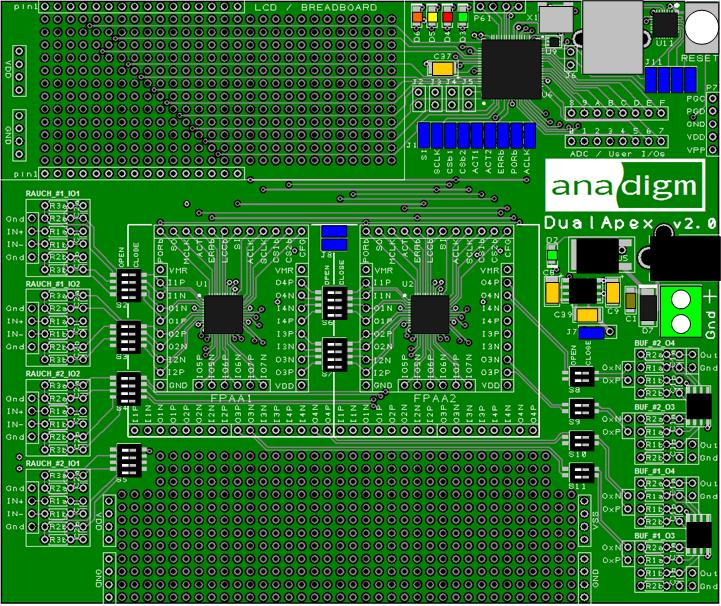

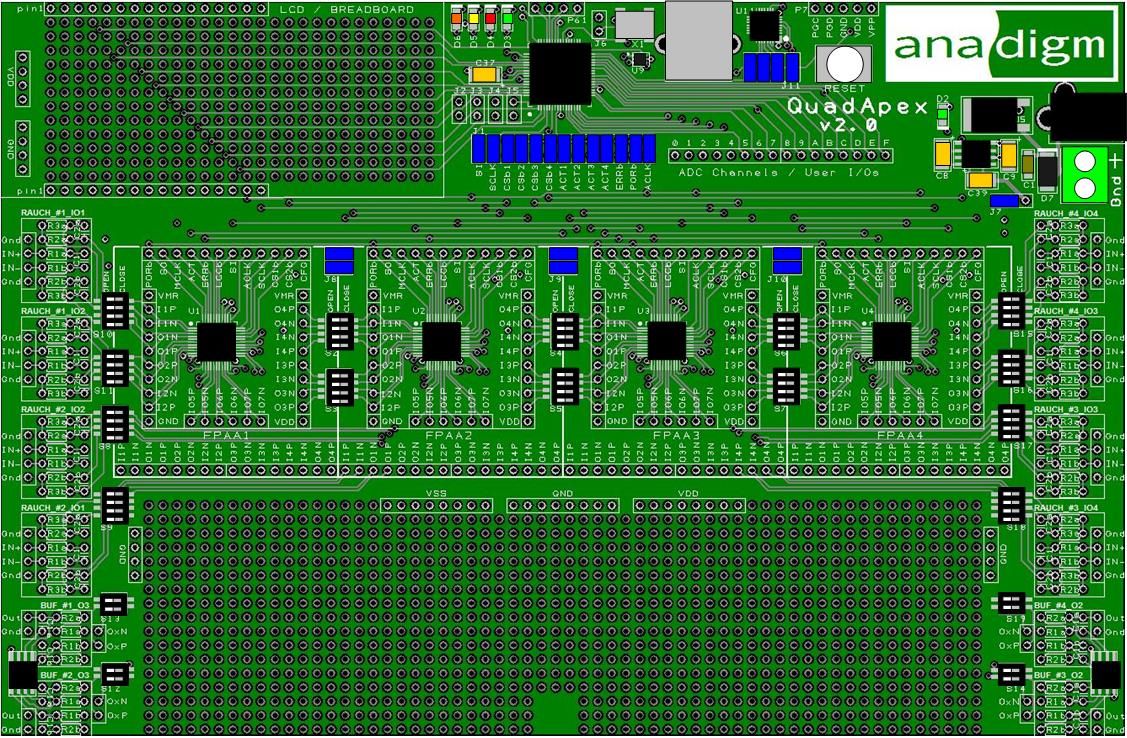

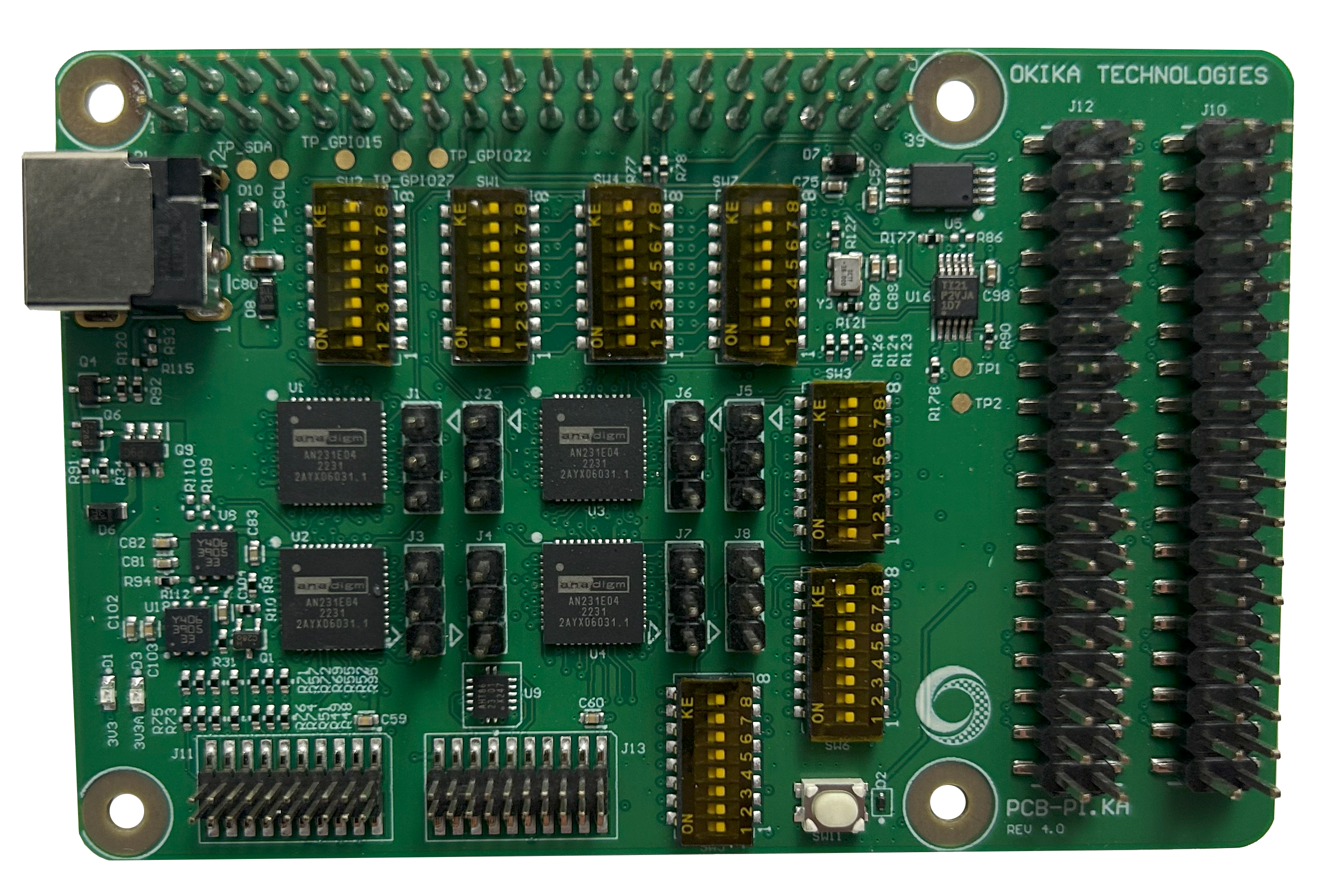

Field Programmable Analog Arrays (FPAAs) provide a promising alternative. By consolidating multiple analog functions into a single reconfigurable device, FPAAs can reduce component count, streamline signal paths, and give engineers tools to optimize performance dynamically. FPAAs are reshaping how engineers approach low-power design, offering new ways to cut energy use without sacrificing performance.

Where Power Is Lost in Analog Systems

Most analog circuits draw power continuously, whether active or idle. Current is consumed across amplifiers, filters, buffers, and repeated signal conversions between analog and digital domains. Designs often plan for worst-case conditions, meaning energy is spent even when workloads are lighter. Redundant circuits and fixed-function boards further add to the baseline draw.

FPAAs reduce this overhead by consolidating functions into a single device and allowing unused circuits to remain inactive. This makes energy use more proportional to actual operating conditions rather than to system-wide worst-case assumptions.

Mechanisms Behind FPAA Efficiency

Consolidation of Functions

An FPAA can replace multiple discrete analog components, reducing both quiescent draw and the energy required for active processing.

Dynamic Reconfiguration

Circuits within an FPAA can be enabled or disabled as needed, aligning consumption with the task at hand.

Reduced Conversion Overhead

By keeping more signal processing in the analog domain, FPAAs cut back on energy-intensive ADC and DAC operations while maintaining responsiveness.

Fine-Grained Bias and Load Control

Modern FPAA architectures give engineers control over bias currents, gain, and routing, making it possible to tune energy use more precisely than with fixed analog designs.

Relevance in Low-Power and Battery-Dependent Designs

Because they minimize idle draw and allow selective activation of circuits, FPAAs are especially well suited for compact, battery-powered applications. In wearables, portable medical devices, or IoT sensors, a single FPAA can handle multiple analog front-end functions while extending operational life and reducing thermal load.Because they minimize idle draw and allow selective activation of circuits, FPAAs are especially well suited for compact, battery-powered applications. In wearables, portable medical devices, or IoT sensors, a single FPAA can handle multiple analog front-end functions while extending operational life and reducing thermal load.

Applications Across Industries

- Aerospace: Satellites and CubeSats operate under strict budgets for power and thermal management. FPAA-based payload interfaces let multiple sensors share a single analog front-end and only activate the required paths during operation.

- Robotics: Autonomous systems rely on diverse analog sensors. FPAAs consolidate front-end functions and allow selective activation, helping balance responsiveness with efficiency.

- Medical Devices: Wearables and diagnostic tools require continuous monitoring without rapid battery drain. Adaptive filtering and amplification within an FPAA preserve fidelity while minimizing unnecessary draw.

- Industrial IoT: Large sensor arrays in automation or monitoring can leverage FPAAs for standby readiness and efficient reallocation of analog resources when active measurements are needed.

Early adoption has been strongest in sectors facing the tightest energy constraints, where improvements in efficiency directly translate into longer mission lifetimes, extended device usage, or reduced operating costs.

Conclusion

FPAAs represent a flexible, forward-looking approach to energy-conscious analog design. By consolidating discrete functions, enabling reconfiguration, and reducing conversion overhead, they can help engineers lower consumption while maintaining performance. Although the technology is still maturing, its potential in aerospace, robotics, medical devices, and industrial IoT is already clear. For engineers facing strict power budgets, FPAAs provide an opportunity to design analog systems that are both efficient and adaptable.