Analog circuits have traditionally been built for fixed inputs and operational conditions. While reliable, this static approach can limit adaptability in modern applications. Satellites may face changing mission objectives. Robotic systems often integrate new sensors over time. Medical devices must meet updated regulatory standards or track emerging biomarkers.

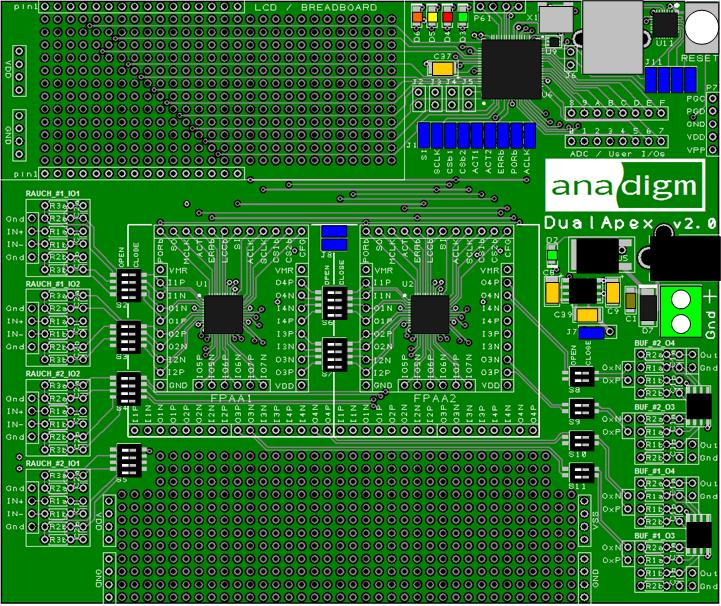

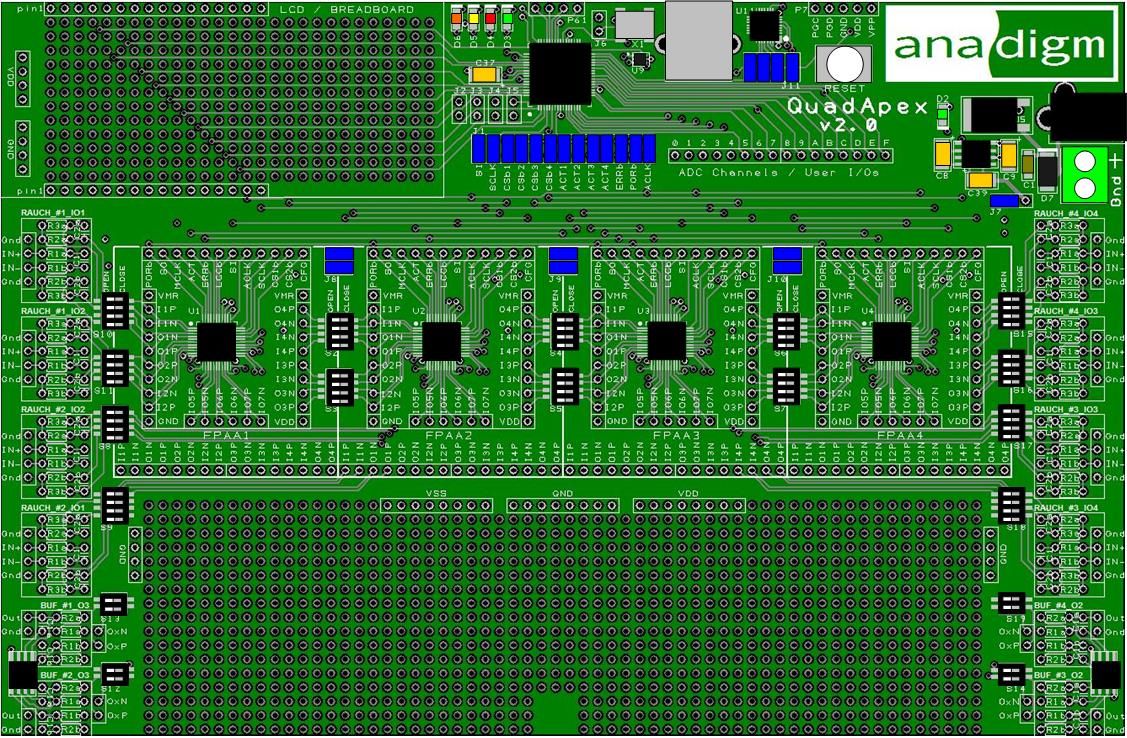

Field Programmable Analog Arrays (FPAAs) provide a way to address these challenges. They enable hardware-level reconfigurability. Engineers can modify analog signal paths, filters, and amplifiers without redesigning entire boards. This can reduce lifecycle costs. It may extend system lifetimes and help keep analog hardware relevant well beyond initial deployment.

Designing Analog Systems for Evolving Requirements

Traditional analog hardware is rigid. Filters, amplifiers, and routing networks are designed for narrow operating ranges. Changes often require full board redesigns, which can be costly and time-consuming. Redesigns typically require validation, testing, and sometimes regulatory approval.

Constraints on size, weight, and power (SWaP) can further limit flexibility. Arrays of discrete components occupy board space and increase energy use. These constraints can reduce instrument density and make adaptation more difficult.

FPAAs can help address these challenges. They consolidate multiple analog functions into a single, programmable device. Unused circuits may be disabled. Signal paths can be reconfigured. New sensor interfaces can potentially be accommodated without replacing hardware. This allows engineers to adapt systems more easily, whether in orbit, in the field, or in clinical settings.

FPAAs can also improve design scalability. Multi-channel analog systems, such as sensor arrays or distributed instrumentation, may be implemented with fewer devices. This can simplify layout, reduce board space, and minimize interconnect complexity.

Accelerating Prototyping and Iteration

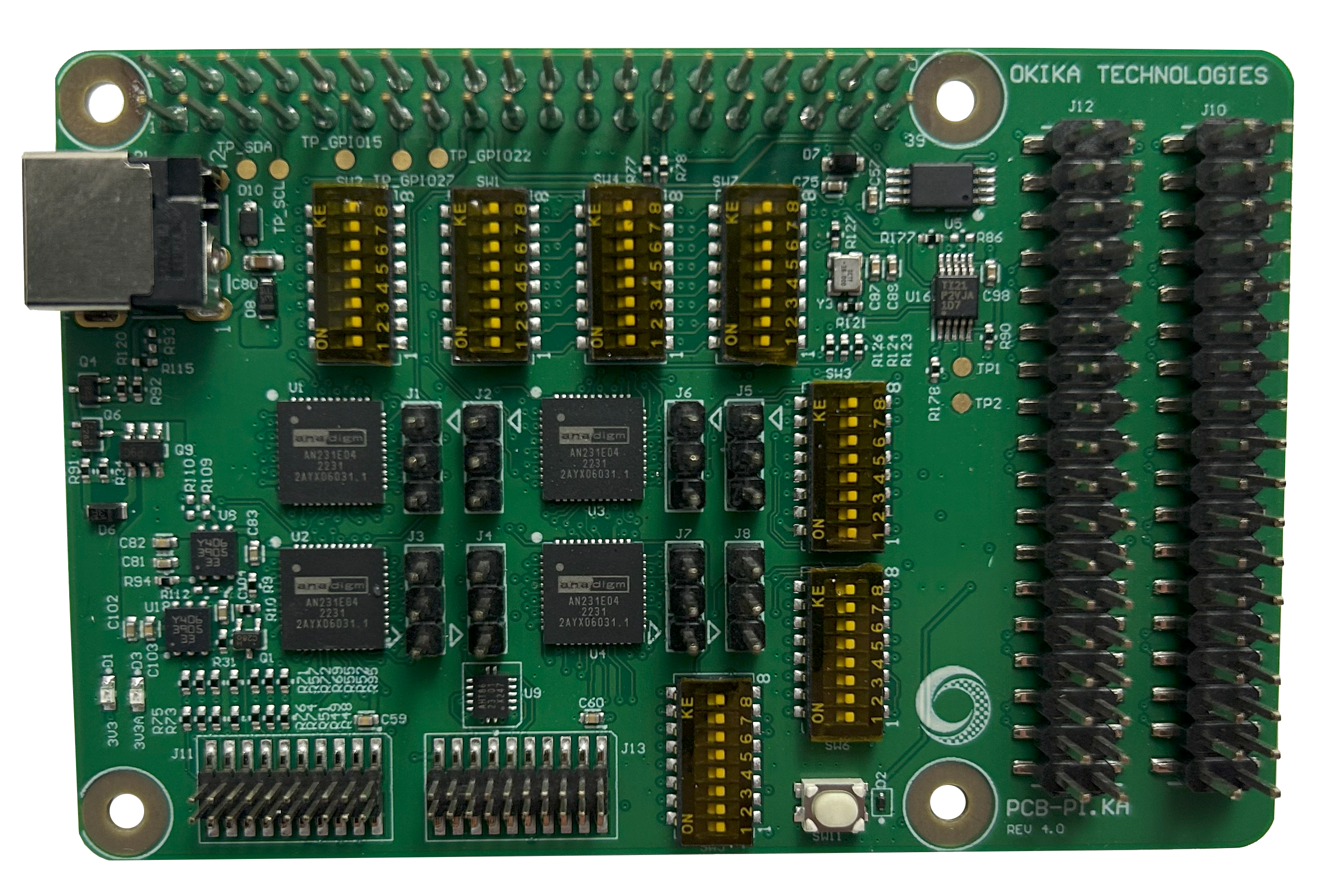

Because FPAA configurations can be updated in software, engineers can prototype new analog circuits more quickly. Multiple configurations can be tested on a single board. This can reduce cycle time from concept to deployment. Engineers may iterate designs without ordering new PCBs, which is especially valuable for embedded systems and IoT applications.

FPAAs can integrate seamlessly with microcontrollers or digital processors. Hybrid analog-digital systems may allow precise control, dynamic reconfiguration, and easier integration with embedded networks or control loops. This flexibility supports complex analog-digital workflows without requiring hardware redesign.

Supporting Lifecycles and Post-Deployment Updates

FPAAs can extend the usable life of analog hardware. Systems may evolve with changing operational requirements, environmental conditions, or mission objectives. Engineers can adjust signal ranges, update filters, or integrate new sensors without full redesigns.

This flexibility may reduce obsolescence and lower lifecycle costs. A single FPAA-enabled board can potentially remain relevant across multiple product generations or mission phases. Native analog processing on the FPAA can help maintain low latency and high performance. It may also support resilience against sensor degradation or unexpected conditions. Analog paths can sometimes be reconfigured to compensate for failing sensors or environmental shifts, which can enhance system reliability.

Applications Across Industries

-

Aerospace: FPAA-enabled payloads can support adjustments to signal conditioning after deployment. Filter bandwidth, gain, and routing may be configured to meet evolving requirements. This approach can reduce redesign overhead and may help accelerate mission updates.

-

Robotics: Automated systems often integrate new sensors or modify operational modes. FPAAs can allow analog signal paths to evolve with perception, control modules, or adaptive navigation systems. This can reduce the need for full board replacements.

-

Medical Devices: Wearable and diagnostic instruments may reconfigure analog front-ends to monitor new biomarkers or comply with updated safety standards. FPAA-based designs can help maintain relevance across multiple product generations.

-

Industrial IoT: Sensor networks in factories or monitoring systems may adapt to evolving data acquisition protocols. FPAA-based processing can allow updates to analog paths without replacing entire sensor boards, minimizing downtime and hardware waste.

Across these applications, FPAAs can help engineers future-proof systems. They may maintain performance under changing conditions and help reduce long-term operational costs. Power efficiency and compact architecture remain additional benefits, especially in SWaP-constrained designs. FPAA adoption is growing in aerospace, robotics, and IoT as engineers explore their flexibility for evolving analog designs.

Conclusion

Field Programmable Analog Arrays change how engineers can approach analog design. They combine dynamic reconfigurability with compact integration. Systems may evolve after deployment. Lifecycle costs can be reduced. Regulatory compliance may be easier to maintain. Performance can remain consistent across changing operational requirements.

For engineers in aerospace, robotics, medical devices, and industrial IoT, FPAAs offer a flexible, resilient, and cost-effective solution. Analog systems no longer need to be static. With FPAAs, adaptability can be built into the hardware, enabling designs that remain relevant over time.