Programmable hardware has long been essential in embedded systems. Engineers are familiar with Field Programmable Gate Arrays (FPGAs) for high-speed digital logic and parallel computation. Field Programmable Analog Arrays (FPAAs) bring similar flexibility to the analog domain, allowing engineers to dynamically configure amplifiers, filters, and routing paths directly in hardware.

By operating on analog signals natively, FPAAs can help reduce latency, lower energy consumption, and save board space. These capabilities are particularly relevant in robotics, medical technology, industrial IoT, and other embedded systems where adaptive signal processing and compact, energy-efficient designs are important.

Understanding the Limitations of Traditional Analog Front Ends

Embedded systems often rely on fixed-function analog circuits. Each sensor or instrument typically requires a dedicated signal chain, including matched amplifiers, tuned filters, and converters optimized for a narrow range of inputs.

This approach introduces several practical challenges:

-

Limited adaptability: Systems cannot easily compensate for sensor drift, evolving measurement requirements, or added instruments.

-

Higher development costs: Adding a new sensor or adjusting operational requirements often triggers a full redesign of interface boards.

-

Resource inefficiency: Arrays of discrete analog components consume board space, increase power draw, and add design complexity.

-

Latency in mixed-signal workflows: Converting analog signals to digital form for processing introduces delays that can be prohibitive in adaptive or high-speed applications.

These constraints create bottlenecks for engineers designing flexible, efficient, and scalable embedded systems.

What Makes Field Programmable Analog Arrays Different

Field Programmable Analog Arrays are programmable hardware fabrics for analog signal processing. A mental model engineers familiar with FPGAs may find useful: an FPAA consists of a network of programmable analog blocks—amplifiers, filters, and switches—that can be configured and routed much like logic blocks and LUTs in an FPGA.

This allows engineers to design analog circuits that are reconfigurable in the field, without replacing hardware. Unlike digital-only solutions, FPAAs operate directly on the analog signal, helping to avoid conversion overhead and maintain low-latency performance.

Key capabilities include:

-

Dynamic Configuration: Amplifiers, filters, integrators, and routing networks can be adjusted as system requirements change. In robotics, control loops may operate with minimal latency. In medical wearables, signal conditioning circuits can occupy less space and consume less power.

-

Hybrid Architectures: FPAAs complement digital processing platforms such as FPGAs or microcontrollers. By combining adaptive analog conditioning with digital computation, engineers can optimize system-level performance.

-

Iterative Development and Deployment: Just as FPGAs allow iterative updates to digital logic, FPAAs allow engineers to iteratively update analog paths. Configurations can be tested, refined, and deployed without redesigning the underlying board.

Advantages of FPAAs for Analog Workloads

FPAAs provide capabilities that FPGAs alone cannot fully deliver in analog processing:

-

Adaptive Signal Processing: Engineers can adjust analog signal paths in real time, helping systems respond to new sensor data, environmental changes, or operational shifts.

-

Potential Power Savings: By avoiding repeated analog-to-digital and digital-to-analog conversions, FPAAs may reduce energy consumption, supporting longer battery life in portable systems.

-

Low Latency: Signals remain in the analog domain, enabling faster feedback loops in robotics or industrial control applications.

-

Compact and Efficient Design: FPAAs consolidate multiple discrete analog components into a single device, saving board space, reducing mass, and simplifying layout. This is valuable for small form-factor embedded systems.

-

Simplified Sensor Integration: Engineers can connect multiple sensor types to a single FPAA, potentially reducing custom interface boards and improving system scalability.

How FPAA Programming Works

Engineers familiar with FPGA toolchains will recognize some similarities. Programming an FPAA typically involves:

-

Designing the analog paths: Choosing which amplifiers, filters, and switches to include.

-

Configuring routing and parameters: Defining gain, filter cutoffs, and signal routing using a vendor-provided design environment.

-

Simulating and verifying: Running circuit simulations to ensure signal fidelity and functional correctness.

-

Deploying configurations: Uploading the analog configuration to the FPAA, which can then execute the design in real time.

This workflow allows engineers to iterate rapidly, test different analog architectures, and adjust circuits post-deployment, all while maintaining consistent signal performance.

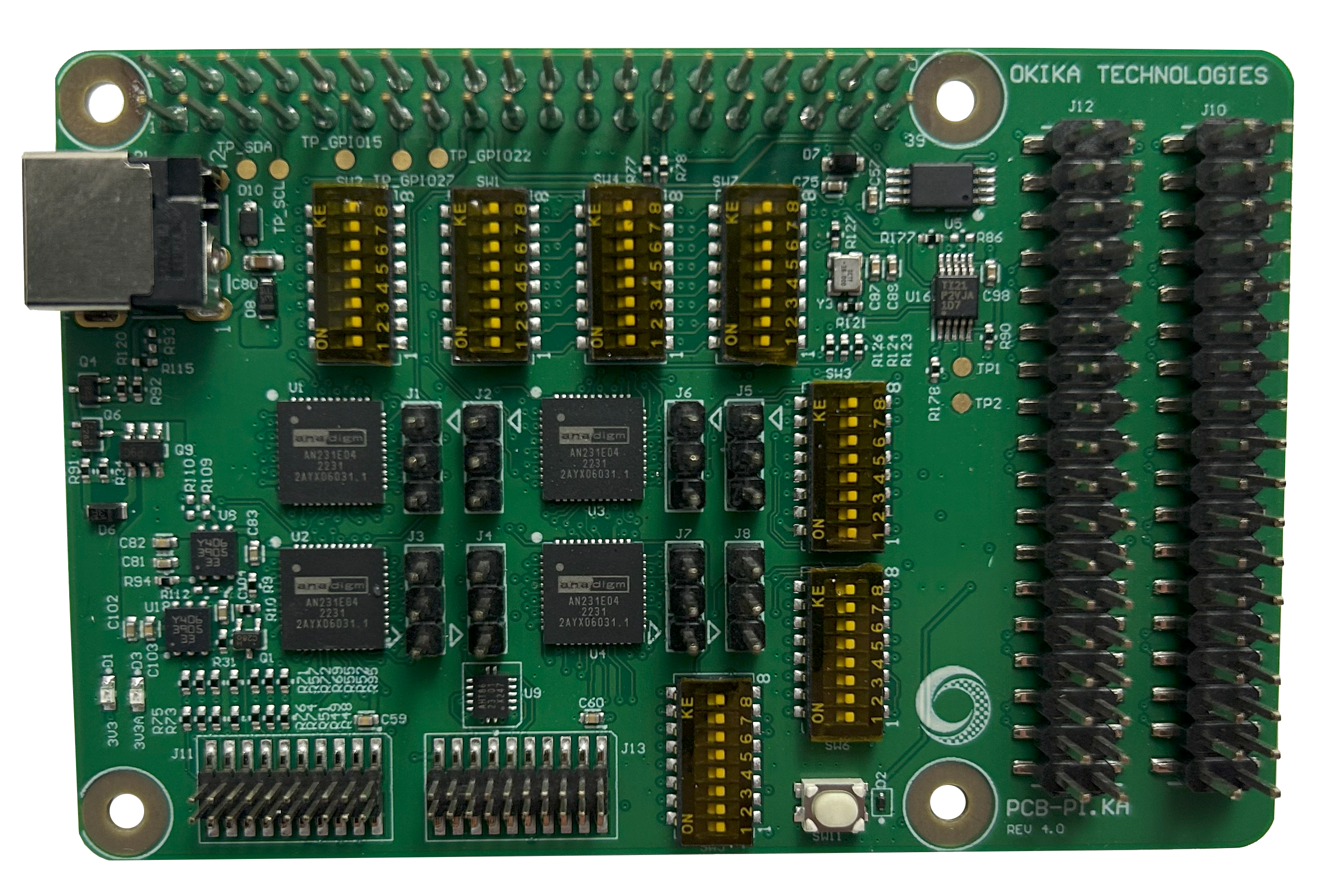

Practical Architectures and Applications

A common FPAA implementation pairs the device with a microcontroller or FPGA. Sensors feed analog signals into the FPAA, which performs filtering, amplification, and impedance matching. A controller can dynamically reconfigure the FPAA and route processed signals to the system bus.

This setup provides tangible benefits:

-

Plug-and-Play Analog Front Ends: Reduces the need for custom interface boards.

-

Low-Latency Processing: Supports high-speed control loops in robotics and industrial automation.

- Compact, Efficient Design: Saves board space and reduces energy usage in wearables and small embedded devices.

-

In-Circuit Reconfiguration: Engineers can dynamically change operating functions, such as frequencies for improved sonar imaging or multiplex multiple sensors through the same hardware resources — all under software control.

-

Field-Deployable Updates: System requirements can evolve without redesigning hardware, supporting lifecycle flexibility.

Reconfigurable analog interfaces are especially valuable in systems with multiple sensors, evolving measurement requirements, or post-deployment updates.

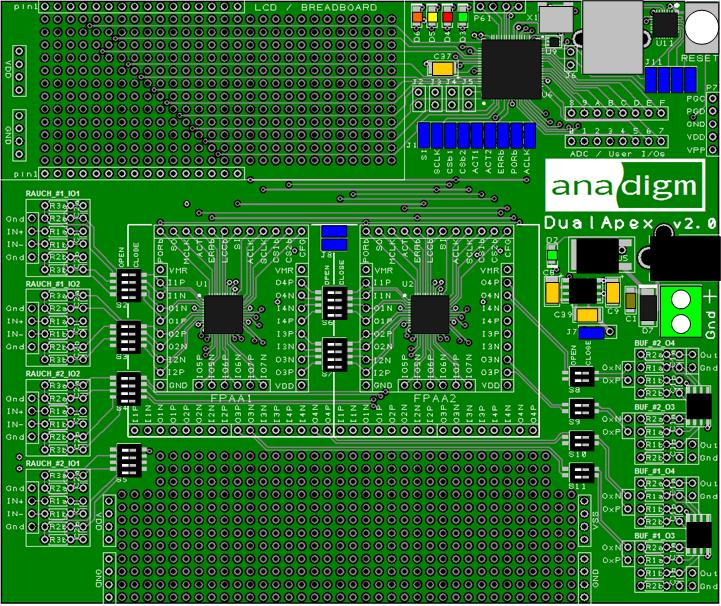

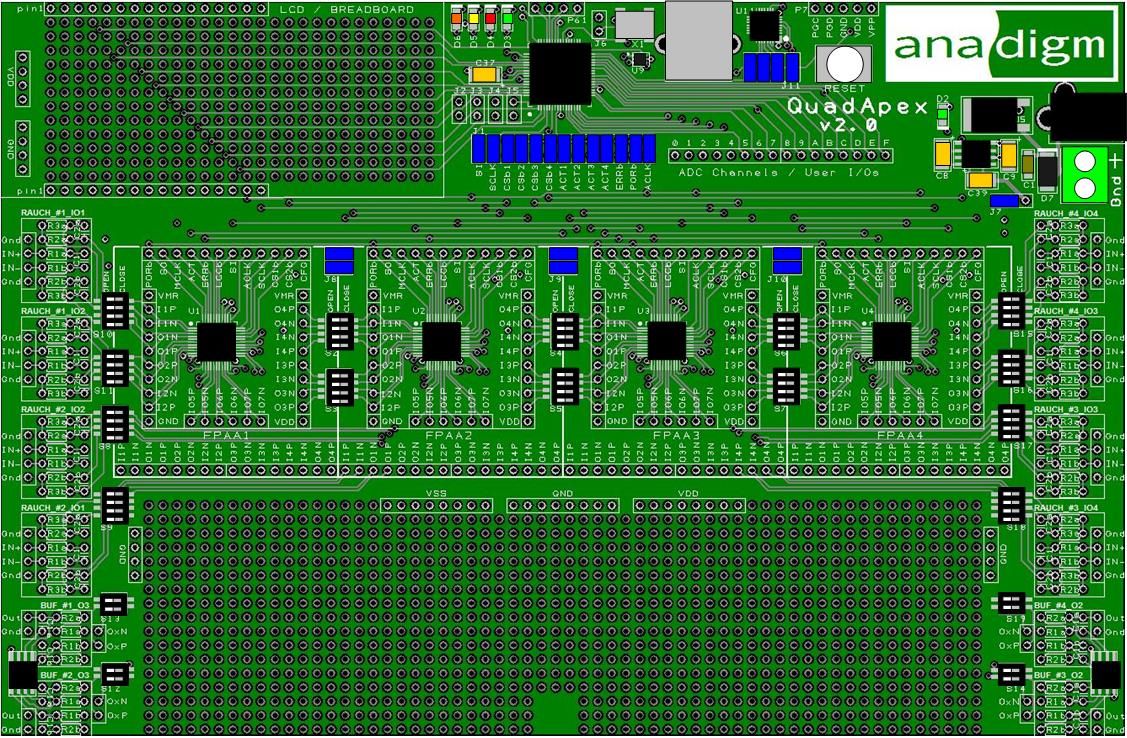

Modern FPAA Architectures

Early FPAA devices had limitations such as narrow bandwidth, limited dynamic range, and complex toolchains. Modern architectures have addressed many of these constraints:

-

Expanded bandwidth may support a wider variety of analog signals.

-

Improved toolchains integrate more seamlessly with FPGA or microcontroller workflows.

-

Lower power operation may benefit energy-sensitive embedded systems.

These enhancements make adaptive analog processing practical for engineers, allowing real-time reconfiguration, miniaturization, and iterative updates in deployed systems.

Conclusion

Field Programmable Analog Arrays extend the flexibility of programmable hardware into the analog domain. Engineers gain tools for adaptive signal processing, low-latency operation, energy efficiency, and space-conscious design.

When combined with FPGAs or microcontrollers in hybrid architectures, FPAAs can transform fixed analog circuits into dynamic, field-updatable systems. This approach supports more resilient, efficient, and scalable embedded designs in robotics, industrial IoT, medical devices, and other applications where analog adaptability and performance matter.